NEW LONDON — After examining sections of the towering Gold Star Bridge with a drone-mounted camera Tuesday, engineers hope to know within days whether Connecticut could use technology to perform some bridge inspections in the future.

If the experiment succeeds, the state could have a way to inspect some bridges more quickly, safely and inexpensively – and with fewer traffic backups — than it does now, according to the Department of Transportation.

With drones being used for tasks from mapping forest fires to scouting for sharks off beachfronts, the DOT is studying whether they could help inspect the state’s highway bridges. The DOT emphasizes that drones wouldn’t replace hands-on inspections, but might be able to handle some of the costlier and harder parts of the job.

“Is this something that’s going to take over the role of people? Absolutely not,” DOT spokesman Kevin Nursick said as contractors flew a drone along the underside of the Gold Star’s northbound span. “But on the larger bridges, we could do some of the work faster.”

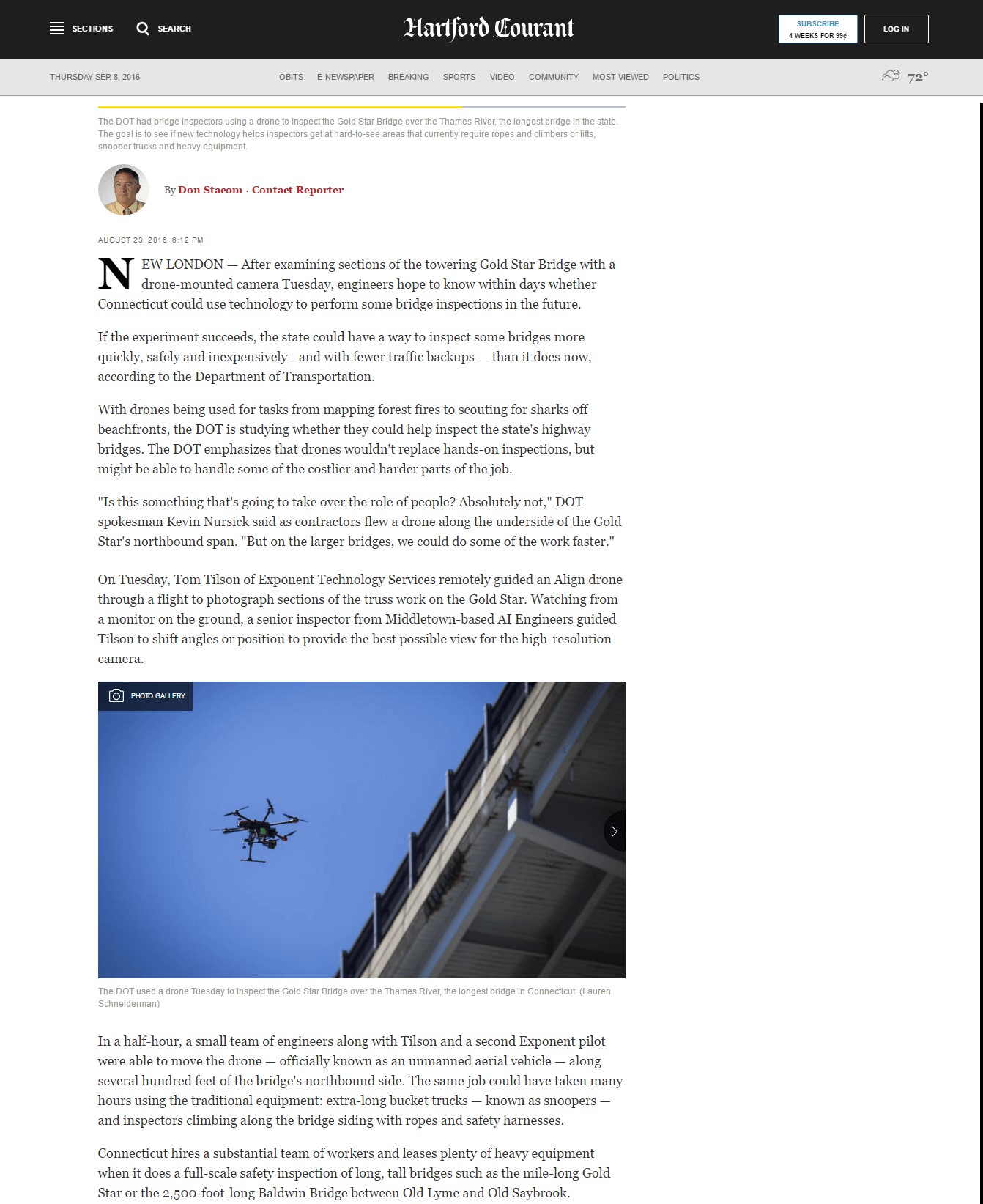

On Tuesday, Tom Tilson of Exponent Technology Services remotely guided an Align drone through a flight to photograph sections of the truss work on the Gold Star. Watching from a monitor on the ground, a senior inspector from Middletown-based AI Engineers guided Tilson to shift angles or position to provide the best possible view for the high-resolution camera.

Gold Star Bridge Inspection

The DOT used a drone Tuesday to inspect the Gold Star Bridge over the Thames River, the longest bridge in Connecticut. (Lauren Schneiderman)

In a half-hour, a small team of engineers along with Tilson and a second Exponent pilot were able to move the drone — officially known as an unmanned aerial vehicle — along several hundred feet of the bridge’s northbound side. The same job could have taken many hours using the traditional equipment: extra-long bucket trucks — known as snoopers — and inspectors climbing along the bridge siding with ropes and safety harnesses.

Connecticut hires a substantial team of workers and leases plenty of heavy equipment when it does a full-scale safety inspection of long, tall bridges such as the mile-long Gold Star or the 2,500-foot-long Baldwin Bridge between Old Lyme and Old Saybrook.

A full-scale inspection of the Gold Star using traditional methods takes about month, even if the state hires four snoopers with crews, said Aslam Siddiqui, executive vice president of AI. Even so, the Gold Star also requires climbers — inspectors on ropes — because snoopers aren’t long enough to reach everywhere on the bridge.

The traditional approach also requires shutting down a lane of traffic, hiring police for traffic control and paying DOT crews to staff the big orange dump trucks that serve as crash barriers to protect workers on the pavement.

The idea behind Tuesday’s experiment is simple: A team of engineers maps out exactly what it wants to see, such as specific spots on the truss work, piers or deck underside. It hires a contractor to supply a drone, then confer extensively with the pilot about precisely where to fly to view specific spots.

Minnesota’s transportation department tested drones for four bridge inspections last year, and concluded that they provide an efficient way to reach some sections of large bridges, particularly hard-to-view areas under the deck.

Connecticut’s DOT is having AI staff compare the images the drone provided on Tuesday with what hands-on inspectors brought back during the Gold Star’s extensive biennial exam last year.

“The willingness to examine new technologies — to innovate and to keep an open mind — is critical if we are to find better ways of doing business,” Commissioner James Redeker said in a statement.